In Focus - Tepla Gigabatch 300 Barrel Etcher

September 2015

Continuing our new series of articles focusing on tools available at the ACT Node, this quarter we look at one of the workhorses of our labs - the Barrel Etcher. Part of our suite of small processing tools purchased to supplement the ‘flagship’ tools, under the direction of the Node Manager Dr Fouad Karouta, this benchtop barrel etcher enhances the Node’s micro- and nano- fabrication capabilities.

The Barrel Etcher is a simple tool using relatively high pressure plasma (generally O2) to remove organic materials and residues from samples and wafers while keeping damage to minimum levels. A number of ‘standard’ processes have been developed in-house to match tools and materials used by our users.

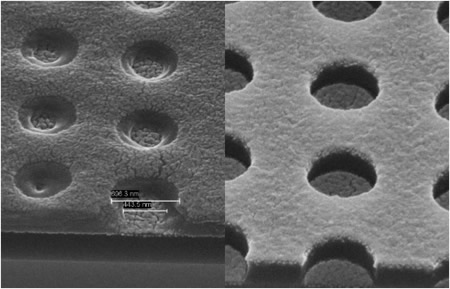

One of the first developed was a short, soft O2 plasma process termed ‘footage removal’ – a process to enhance pattern definition after e-beam lithography (EBL) and optical lithography – as shown in Figure 1 (left). Here you can clearly see the footage removal benefit as the image on the right shows a well-defined pattern compared to the image on the left before O2 plasma treatment. Feature sizes in these images is approximately 500nm. This is used mostly for removal of positive resists such as PMMA and ZEP used in EBL, or applied to positive resists used in optical lithography.

One of the first developed was a short, soft O2 plasma process termed ‘footage removal’ – a process to enhance pattern definition after e-beam lithography (EBL) and optical lithography – as shown in Figure 1 (left). Here you can clearly see the footage removal benefit as the image on the right shows a well-defined pattern compared to the image on the left before O2 plasma treatment. Feature sizes in these images is approximately 500nm. This is used mostly for removal of positive resists such as PMMA and ZEP used in EBL, or applied to positive resists used in optical lithography.

Another process was developed to remove organic resists that had been exposed to Cl2 or ion irradiation that hardens the resist making it non-dissolvable in acetone. In this case high power O2 plasma is the only choice to remove this hardened layer.

Another important application considered at purchase required the fitment of a second gas line supplying CF4 – III-V semiconductor nanowires (NW) used in device applications. This technique involves planarising the NW sample with benzo-cyclo-butene (BCB) and etching back the polymer with both CF4 and O2 to uncover the NWs and finally depositing a metal electrode for electrical contacting – hence the two gas lines.

Fouad was also interested in developing an O2 process to remove chromium (Cr), a metal often used as a SiOx etching mask for high aspect ratio structures. Certain Cr oxides are volatile but only at high pressures (around 1 mBar) so the barrel etcher was retrofitted with a butterfly valve to facilitate the pressure increase. With this addition it is possible to fully remove a 50nm Cr layer using purely O2 plasma in about 30 minutes. This process is highly selective of other materials like SiOx, Si and III-V semiconductors.

One final benefit of the system is the ability to run processes using a Faraday cage to further reduce ion bombardment of the sample during the plasma process.

Please contact our staff if you think the barrel etcher can be useful to your research or device development.